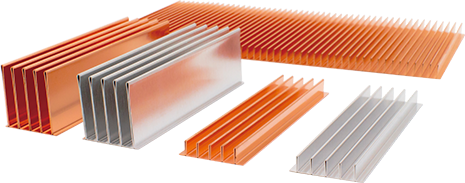

Folding fins®

What is Folding fins?

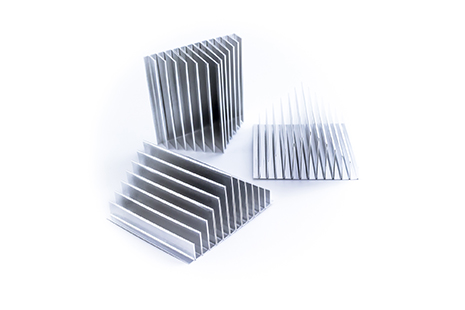

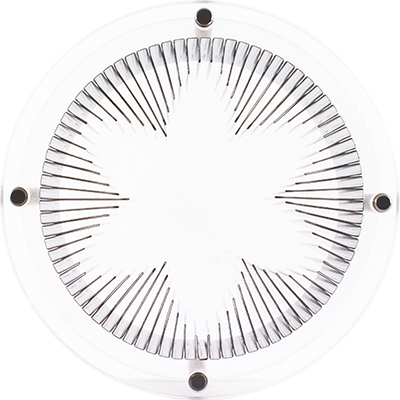

They are formed by a manufacturing method different from that of ordinary thin sheet metal fins and any dies wonʼt be used. Characteristic is the shape folded one by one.

Thickness, pitch and height can be freely designed and thus they can be ordered from one piece.

The feature

By developing unique processing method,elements that can solve customersʼ troubles have further increased.

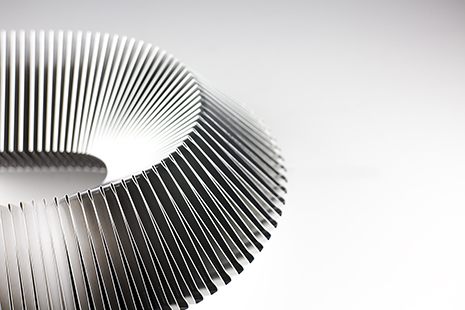

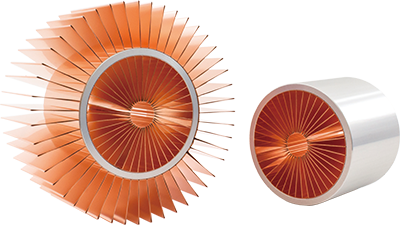

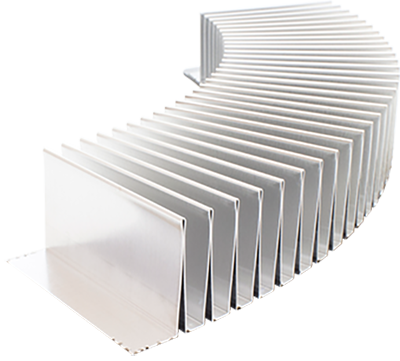

Flexible

On curved surface, cylinder etc. Greater flexibility over installation spots.

Pitch and height can be freely designed by changing programs.

Greater flexibility over minor specification changes.

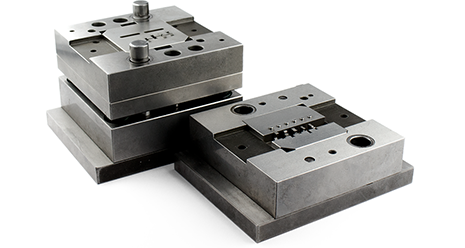

Saving initial cost and time

Without using any metal dies.

Divelopment of unique manufacturing methods.

There are installation methods suitable for application

There are installation methods suitable for application

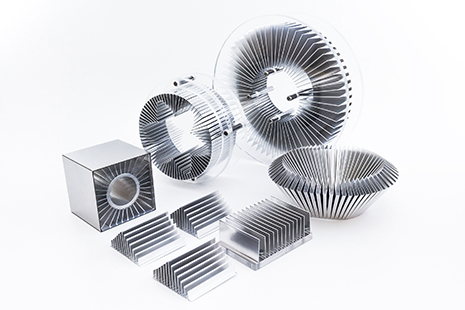

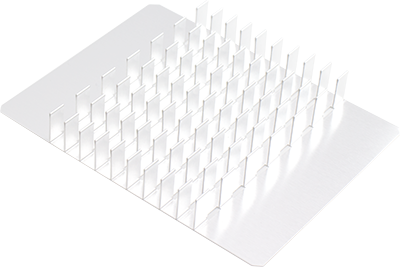

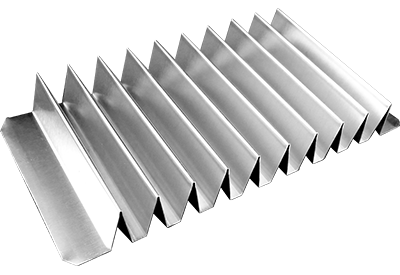

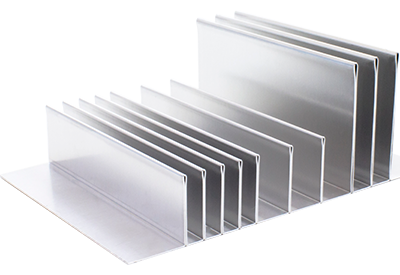

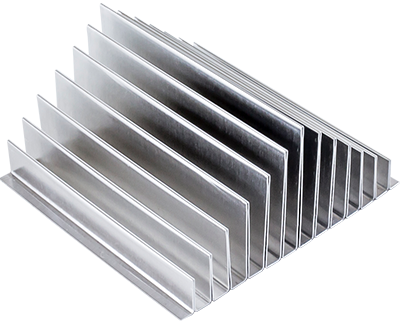

Shapes of thin sheet metal fins

There are as many variations as the number of needs. Variations can expand infinitely because developers can order optimum products for any of their designs.

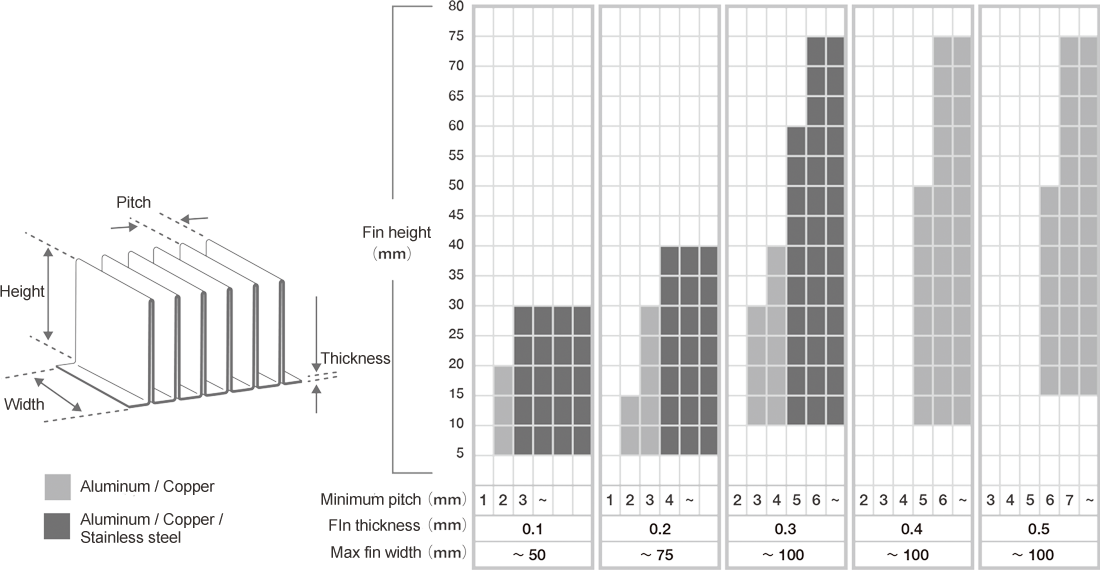

About manufacturing availabilities

Estimated manufacturable range

The shapes within the following range are available at the momet.

Even fins with dimensions outside the range may be manufacturable. So please feel free to contact us.

✳ Consultation necessary about manufacturable area of wavy shapes.